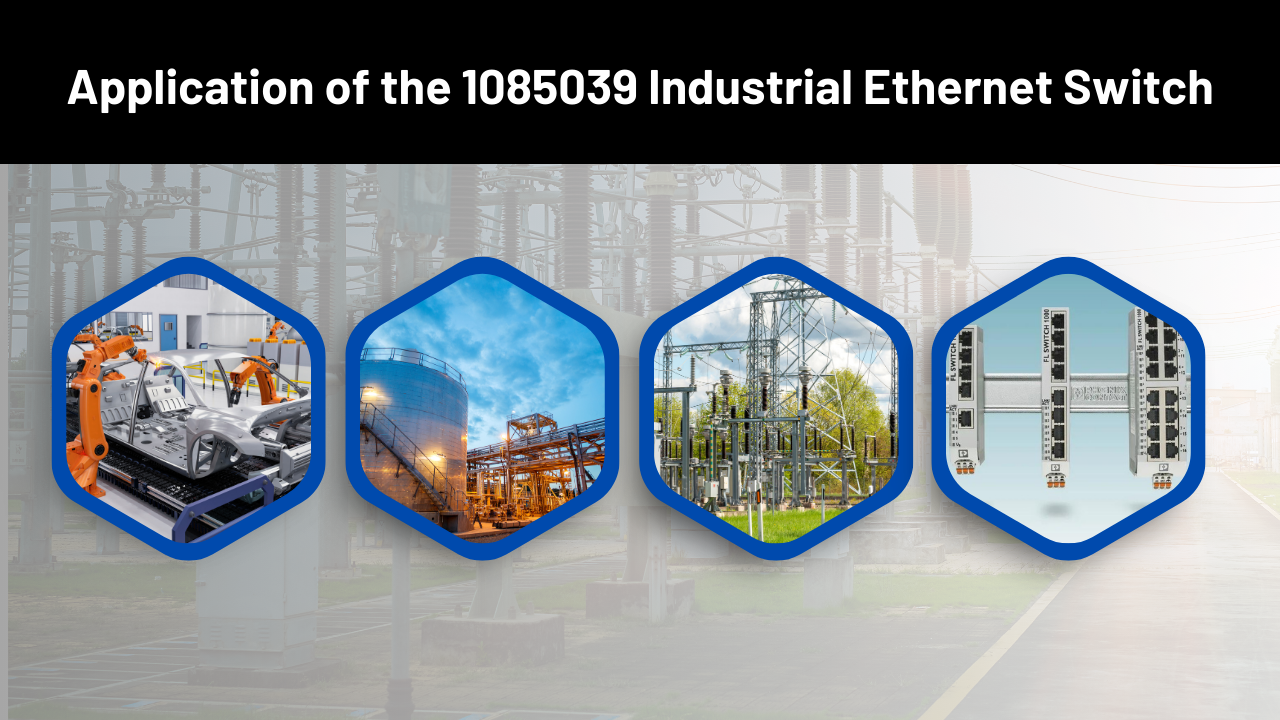

The 1085039 Industrial Ethernet Switch is a particular product model number, and its features and specifications will determine how it is used in most cases. Industrial Ethernet switches are frequently used for networking in a variety of industrial contexts, especially those that need flexibility, resilience, and dependability. The following are a few possible uses for the 1085039 Industrial Ethernet Switch:

1.Factory Automation: Industrial Ethernet switches are used in manufacturing facilities to link different types of machinery and equipment, enabling real-time control, monitoring, and data sharing. The switches provide predictive maintenance and aid in efficiency gains and manufacturing process optimization.

- Machine Connectivity: Conveyors, assembly lines, CNC machines, and robots are examples of manufacturing equipment that is connected via industrial Ethernet switches. These devices can link to one another quickly and reliably thanks to the 1085039 switch, which makes it possible to coordinate and manage production processes with ease.

- PLC and SCADA Integration: Systems for supervisory control and data acquisition (SCADA) and programmable logic controllers (PLCs) are crucial for keeping an eye on and managing industrial processes. Real-time data interchange for effective process management is ensured by the Ethernet switch, which facilitates connectivity between PLCs, SCADA servers, and other control devices.

2.Transportation Systems: In transportation networks including seaports, airports, and railroads, industrial Ethernet switches are essential components. They ensure efficient operations and passenger safety by facilitating communication between various subsystems, such as ticketing machines, traffic control systems, and security cameras.

3.Power Substations: In power substations, Ethernet switches are used to link sensors, monitoring equipment, and control systems. They make it possible for power distribution equipment to be remotely monitored and controlled, which aids utilities in maintaining grid stability, effectively managing energy, and promptly responding to problems.

4.Oil and Gas Industry: Industrial Ethernet switches are used in oil refineries, offshore platforms, and pipeline networks to facilitate data transfer between different components, including sensors, pumps, valves, and control systems. They facilitate vital functions such as safety shutdowns, control, and remote monitoring.

- Safety and Emergency Shutdown Systems: Safety-critical applications like emergency shutdown devices (ESDs) and fire and gas detection systems depend heavily on industrial Ethernet switches. These switches offer dependable channels of communication for the transmission of alerts and safety signals, enabling quick emergency action and lowering dangers to people and property.

- Offshore Platform Communication: Ethernet switches are used to provide communication networks aboard platforms and FPSOs (Floating Production, Storage, and Offloading vessels) in offshore oil and gas production facilities. To ensure effective operation and maintenance of offshore assets, the 1085039 switch offers high-bandwidth data transfer between production equipment, control systems, and distant monitoring centers.

- Cybersecurity and Network Resilience: To defend vital infrastructure from cyberattacks, industrial Ethernet switches like the 1085039 model have cybersecurity capabilities including intrusion detection, encryption, and access control. These switches also feature robust environmental resistance, guaranteeing dependable operation in challenging onshore and offshore settings.

Check :- 1085039 Industrial Ethernet Switch

5.Building Automation: Ethernet switches are essential components of building automation systems, facilitating the integration of lighting, security, HVAC (heating, ventilation, and air conditioning), and access control systems. They make it possible to monitor and control building operations centrally, maximizing energy efficiency and improving occupant safety and comfort.

6.Smart Cities: For the purpose of integrating waste management systems, traffic signals, lamps, and environmental sensors, industrial Ethernet switches are used in smart city efforts. They provide novel citizen services and enable data interchange, serving as the backbone of smart city networks.

7.Water and Wastewater Treatment: PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, actuators, sensors, and other components are connected in water and wastewater treatment facilities using industrial Ethernet switches. They ensure regulatory compliance and save operating costs by supporting real-time monitoring, control, and optimization of water treatment operations.

- Process Control and Automation: Pumps, valves, sensors, actuators, and other components of water and wastewater treatment operations are all connected by industrial Ethernet switches. The supervisory control and data acquisition (SCADA) system and these devices may communicate in real time thanks to the 1085039 switch, which makes it possible to precisely regulate and automate treatment operations including coagulation, flocculation, sedimentation, filtration, and disinfection.

- Remote Monitoring and Management: Operators of water treatment plants may set up reliable communication networks for remote infrastructure control and monitoring with the 1085039 switch. This entails keeping an eye on equipment condition, flow rates, pressure levels, and water quality data from a single control center. Through remote access made possible by the switch, operators may minimize downtime and guarantee continuous operation by quickly responding to alerts, running diagnostics, and troubleshooting problems.

8.Mining Operations : Industrial Ethernet switches are used in mining situations to provide robust, high-bandwidth networks that link monitoring systems, trucks, and mining equipment. Through the provision of real-time data communication and control, they improve mining operations’ safety, productivity, and efficiency.

Network dependability and efficiency in our industrial setting have increased dramatically since the 1085039 Industrial Ethernet Switch was installed. We are able to exert more control over our network infrastructure by taking use of its sophisticated features, which include high-speed data transfer, strong industrial design, and support for industrial protocols. Thanks to the switch’s smooth communication throughout all of our operating units, downtime has been significantly reduced and overall productivity has increased. Furthermore, long-term durability and compatibility with our current systems are guaranteed by its ruggedized structure and adherence to industrial standards.